about

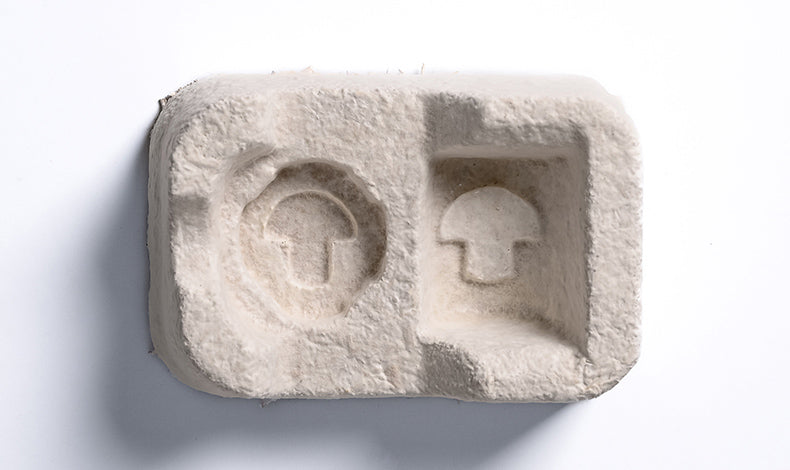

To combat styrofoam and plastic waste, Ecovative Design LLC created a new compostable packaging material by growing mycelium together with agricultural matter, what we’ve named MycoComposite™ technology. Our Mushroom® Packaging is 100% home and marine compostable at the end of use.

Mushroom® Packaging is a division of Ecovative, the world’s leading mycelium technology company. Mushroom® Packaging focuses on producing custom-molded protective packaging parts, and licensing Ecovative’s MycoComposite™ technology to other companies for a variety of applications.

What is Mushroom® Packaging?

Mushroom® Packaging produces high-performing, sustainable packaging solutions grown from mycelium, the “roots” of mushrooms. Called MycoComposite™, this material is made with two simple ingredients — mycelium and hemp hurd — offering a regenerative alternative for the plastic foams used in protective packaging. Unlike plastics, our packaging is home-compostable in 45 days, adding nutrients to the soil instead of pollution. Mushroom® Packaging is also a cost- and performance-competitive solution for custom-molded products.

Mushroom Packaging is

- 1

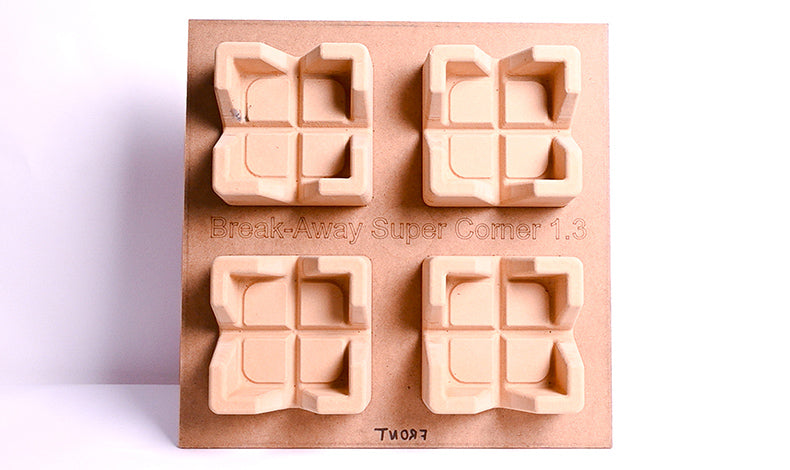

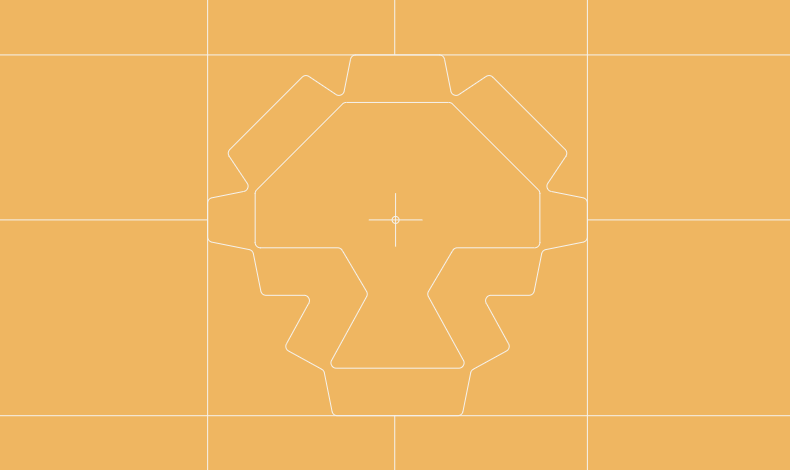

Grown to shape in only 7 days, no post-processing required

- 2

Custom molded at a fraction of the cost of foam packaging

- 3

Flame resistant, due to inherent properties of mycelium

- 4

Biodegradable and fully home-compostable, returning nutrients back to the earth

- 5

Naturally water resistant (hydrophobic), making it suitable for thermal applications and shipping with ice packs that are subject to melting

- 6

An active soil amendment, strengthens the growth of plants

Compostability

Mushroom® Packaging is fully home-compostable and Cradle to Cradle Gold Certified. Whereas many products that claim to be compostable require energy-intensive processing, Mushroom® Packaging naturally reverts to soil nutrients after just 45 days.

Simply break up the packaging into small pieces, and toss them into the compost bin or spread them throughout your garden. While it is possible to dispose of Mushroom® Packaging in the garbage or industrial compost bin, we recommend home composting. Mushroom® Packaging is a natural fit for the circular economy, creating self assembling, high value products from agricultural waste, reducing pollution and nourishing the planet at the same time.

Shelf Life

30 years, if kept in standard dry storage conditions

Industry Recognized Certifications

Biodegradable Product Institute (ASTM D6400, soil toxicology)

USDA Biobased Preferred (ASTM D6866)

International Living Future Institute, Declare Red-List Free

VOC (ASTM D1333) and Aldehyde Free (ASTM D6007)

GHG Reduction

Every year, Americans alone use an incredible 900,000 metric tons of plastic foam protective packaging. When you account for the embodied energy and fossil fuels involved, that’s around 1.5 million metric tons of petroleum. A comprehensive Life Cycle Assessment found that Mushroom® Packaging consumes only a tenth of the energy for an equivalent volume of foam, with only an eight of the greenhouse gasses.

Feedstock/Raw Materials

Mushroom® Packaging is made from hemp hurd, which we upcycle from the waste streams of the fiber hemp industry. This is done through a process called decortication, where the fiber is stripped from the hemp plants and separated for use in various industries, like textiles and ropes. We use the spongy hurd (or pith), which our mycelium loves to eat, binding together into a lightweight, solid material. Fun fact: hemp sequesters more carbon per acre than any other commercial crop.

Basic Terminology

Recyclable: Capable of being taken apart into its basic components to be re-used for the same use, or for another purpose entirely.

Biodegradable: Can be broken down and metabolized by animals or microbes to become nutrition for other parts of the ecosystem.

Degradable: Can break down into smaller pieces not necessarily useful to living organisms. Plastics, for example, can degrade but are not biodegradable.

Compostable: Able to biodegrade into nutrients for the Earth, breaking down quickly under defined conditions that support plant growth and soil health.