Our Process

Our packaging is grown, not manufactured.

We offer a high-performing, cost competitive packaging solution which is naturally thermally insulating and water resistant. Mushroom® Packaging grows in 7 days using mycelium, the roots of mushrooms, as the biological binder, and is fully home-compostable in 45 days.

Once we’ve identified the opportunity fit, we’ll look to connect you with the appropriate Mushroom® Packaging licensee for your region.

Mushroom® Packaging is

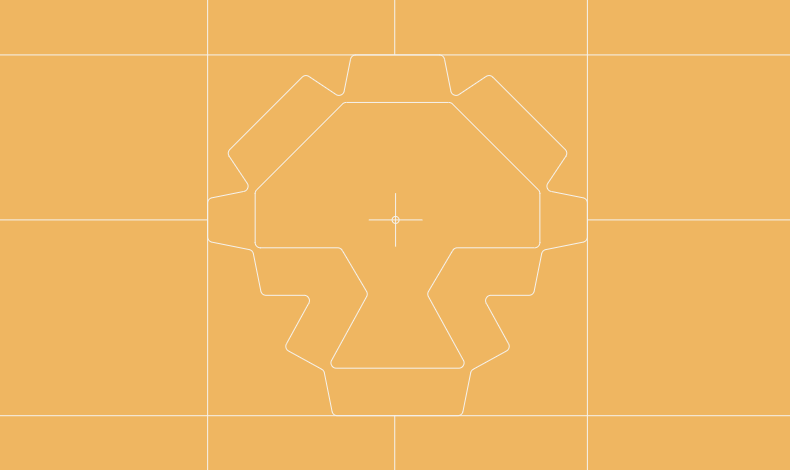

CAD

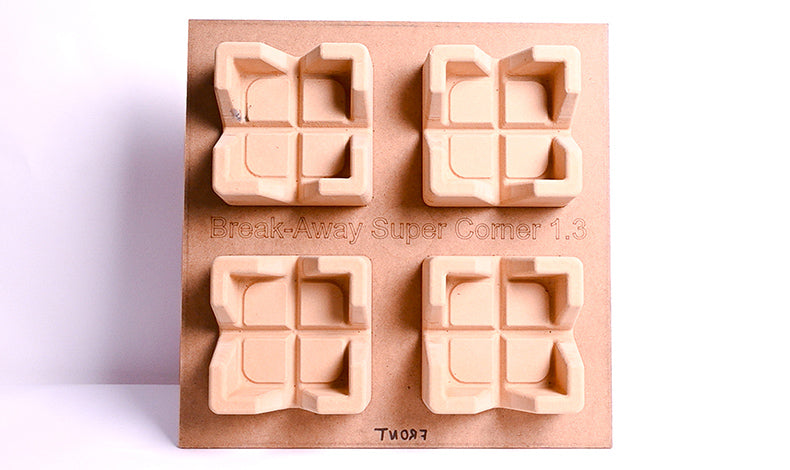

1CNC Milling

2

Hard Tooling

3Thermoform Growth Trays

4Fill Parts with Hemp & Mycelium

5Internal Growth in Pod

6Pop Parts

7External Growth in Pod

8Dry Parts

9Our process. Step by step.

Our designers generate a 3D model of your Mushroom®Packaging insert and route a positive using a CNC machine.

We thermoform the positive to make growth trays — which are reused numerous of times.

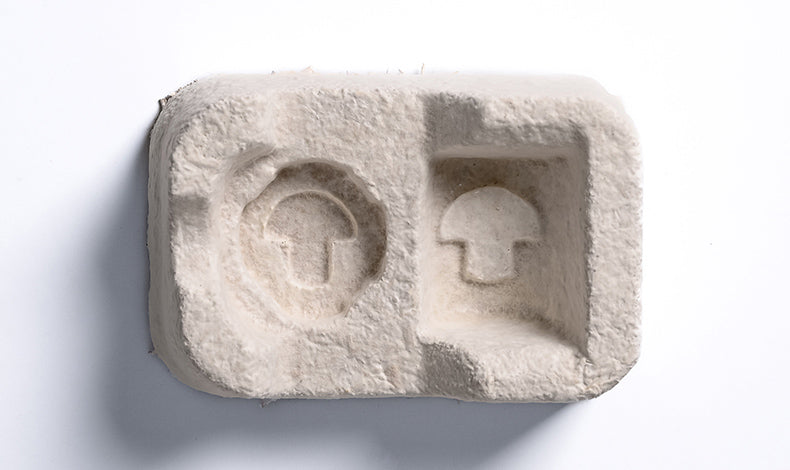

The trays are filled with our hemp hurd and mycelium blend which grow for 4 days.

The grown parts are removed from the tray and continue to grow for 2 more days to create a velvety layer of overgrowth.

The parts are dried to disable future growth. The Mushroom® Packaging is ready to protect your product in shipment.

Custom Design Timeline

Phases and lead times for the Mushroom® Packaging

Custom Design Process & OverviewCustom Design Timeline

Phases and lead times for the Mushroom® Packaging

Dimension Drawing + Render

1-2 business days per iteration

Custom Grown Prototype

3-4 weeks per iteration

Quote + PO

1 week

Includes production tooling costs and per-piece price.

Tooling + Pilot Run

3–4 weeks

Production

6–12 weeks

Lead time varies by licenses, annual volume needs and tooling investment.

Design Constraints

Guidelines and Considerations for Mushroom® Packaging

Maximum Part Dimensions:

18 x 18 x 5”

Smaller parts fit multiple per tray.

Fill surface

After Popping

Fill Surface + Flash

Every tray is filled in one direction, typically on the bottom because it is flat. The fill surface texture is rougher than the molded surface.

Velvety Overgrowth

4 days in tray (internal growth)

2 days no tray (external growth/ overgrowth)

1 day to dry, preventing further growth and fruit mushrooms.

Contraction

Parts must be scaled up since they shrink when drying:

4% in the x axis

4% in the y axis

7% in the z axis

Incorrect

Correct

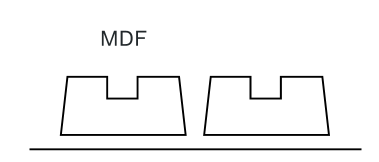

Draft Angles

At least a 3 degree draft angle on all vertical walls, with no undercuts

Wall Thickness

Minimum of ⅜” to to avoid voids. Avoid large, thin walls which can warp and are structurally weak.

Edges

Fillet all edges with a minimum radius of 0.125”

Draw Ratio

The draw ratio should be at least 1 unit wide by 1 unit tall. Avoid deep cavities.

Orientation

Standing upright on shelves is not recommended due to draft angles. Product will tilt downward and could fall.